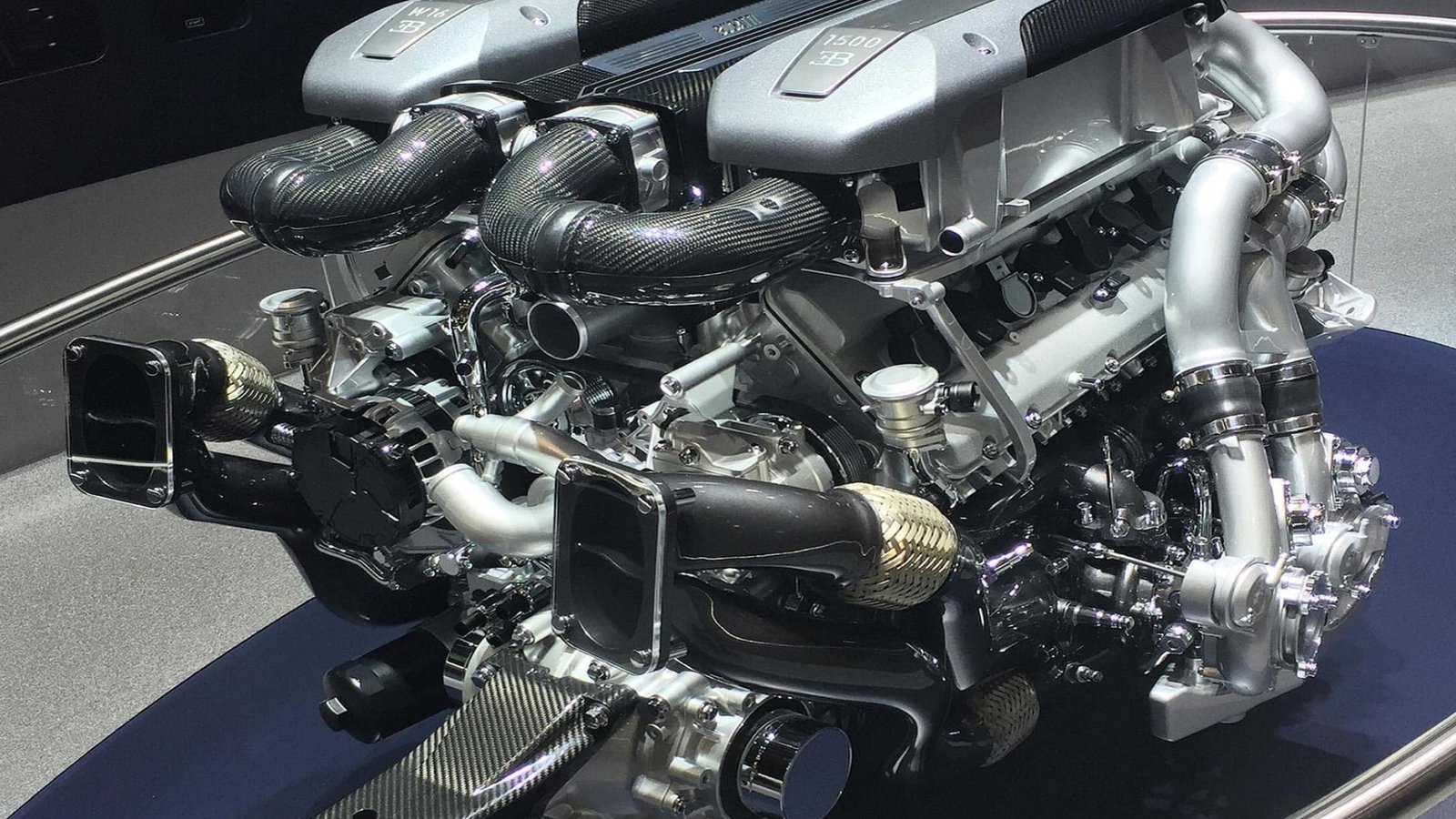

High-performance engines are designed to deliver superior power, speed, and responsiveness compared to standard engines. They are built with advanced technologies and materials that enhance their efficiency and capability. If you’re curious about what makes high-performance engines stand out, this guide will delve into their unique features, design elements, and the benefits they offer.

1. Advanced Engineering

1.1 Superior Design

Overview: High-performance engines are engineered with precision to maximize efficiency and power output. They often feature innovative designs that enhance performance.

Design Features:

- Turbocharging: Boosts engine power by forcing extra air into the combustion chamber.

- Intercoolers: Cool the compressed air from the turbocharger, increasing engine efficiency.

Benefits:

- Increased Power: Delivers greater horsepower and torque.

- Enhanced Efficiency: Improves overall engine performance and fuel economy.

1.2 High-Quality Materials

Overview: To withstand higher stress and temperatures, high-performance engines use advanced materials.

Materials Used:

- Forged Pistons: Stronger and more durable than cast pistons.

- Titanium Valves: Lightweight and resistant to high temperatures.

Benefits:

- Increased Durability: Resists wear and tear under high performance.

- Reduced Weight: Lightweight materials improve engine responsiveness.

2. Enhanced Cooling Systems

2.1 Improved Cooling Technologies

Overview: High-performance engines generate more heat due to increased power output, so advanced cooling systems are essential.

Cooling Technologies:

- Upgraded Radiators: Larger and more efficient radiators to manage higher heat levels.

- Oil Coolers: Prevent engine oil from overheating.

Benefits:

- Prevents Overheating: Keeps the engine within optimal temperature ranges.

- Maintains Performance: Ensures consistent power output and efficiency.

2.2 Effective Heat Management

Overview: Effective heat management is critical in high-performance engines to prevent damage and ensure reliability.

Heat Management Techniques:

- Heat Shields: Protect sensitive components from excessive heat.

- Ceramic Coatings: Applied to exhaust components to reduce heat transfer.

Benefits:

- Extended Engine Life: Reduces thermal stress on engine parts.

- Improved Reliability: Maintains performance under high-stress conditions.

3. Advanced Fuel Injection Systems

3.1 Precision Fuel Delivery

Overview: High-performance engines often utilize advanced fuel injection systems to optimize power and efficiency.

Fuel Injection Technologies:

- Direct Injection: Delivers fuel directly into the combustion chamber for better atomization and combustion.

- Variable Valve Timing: Adjusts valve timing for improved power and efficiency.

Benefits:

- Increased Power: Enhances throttle response and acceleration.

- Better Fuel Economy: Improves combustion efficiency, reducing fuel consumption.

3.2 Tuned Performance

Overview: Performance-tuned fuel injection systems are calibrated to maximize engine output and responsiveness.

Tuning Aspects:

- Custom Maps: Engine control units (ECUs) use custom fuel maps to optimize performance.

- Dynamic Adjustments: Real-time adjustments based on driving conditions and load.

Benefits:

- Enhanced Acceleration: Provides quicker and more responsive acceleration.

- Optimized Performance: Tailors engine performance to specific driving needs.

4. High-Performance Exhaust Systems

4.1 Advanced Exhaust Design

Overview: High-performance engines often feature specialized exhaust systems designed to improve airflow and reduce back pressure.

Exhaust Technologies:

- High-Flow Headers: Improve exhaust gas flow and reduce restrictions.

- Performance Mufflers: Enhance exhaust sound and reduce weight.

Benefits:

- Increased Power: Reduces exhaust back pressure, boosting engine performance.

- Better Sound: Produces a more aggressive and appealing exhaust note.

4.2 Enhanced Gas Flow

Overview: Efficient gas flow through the exhaust system is crucial for maintaining high engine performance.

Gas Flow Improvements:

- Smooth Tubing: Features smooth bends and larger diameter pipes for improved flow.

- Thermal Coatings: Reduce heat buildup in exhaust components.

Benefits:

- Improved Efficiency: Enhances engine breathing and performance.

- Reduced Heat: Lowers temperatures in the engine bay and exhaust system.

5. Optimized Engine Management

5.1 Advanced Engine Control Units (ECUs)

Overview: High-performance engines use sophisticated ECUs to manage various engine functions and optimize performance.

ECU Features:

- Real-Time Monitoring: Continuously monitors engine parameters and adjusts settings.

- Custom Tuning: Allows for custom performance tuning and adjustments.

Benefits:

- Enhanced Control: Provides precise control over engine performance and response.

- Improved Efficiency: Maximizes power output while maintaining fuel efficiency.

5.2 Performance Tuning

Overview: Performance tuning involves adjusting engine settings and parameters to enhance power and responsiveness.

Tuning Methods:

- Dyno Tuning: Uses a dynamometer to measure and adjust engine performance.

- Chip Tuning: Reprograms the ECU for improved performance.

Benefits:

- Custom Performance: Tailors the engine’s performance to specific driving needs and preferences.

- Maximized Output: Extracts the highest possible power and efficiency from the engine.

Conclusion

High-performance engines are distinguished by their advanced engineering, high-quality materials, and specialized components designed to deliver superior power and efficiency. From enhanced cooling systems and precision fuel injection to advanced exhaust designs and optimized engine management, these engines are built to perform at the highest level. Understanding what makes high-performance engines special can help you appreciate the technology and design that contribute to their exceptional capabilities. Whether you’re an enthusiast or simply curious, these features highlight the cutting-edge advancements in automotive engineering that push the boundaries of performance.