Engine technology has come a long way, with continuous advancements aimed at improving performance, efficiency, and environmental impact. From new materials and design philosophies to groundbreaking technologies, here’s a look at the latest innovations in engine technology shaping the future of automotive performance.

1. Electric and Hybrid Engines

1.1 Fully Electric Engines

Overview: Electric engines, powered entirely by electricity, are becoming increasingly popular as the automotive industry shifts towards zero-emission vehicles.

Recent Developments:

- Improved Battery Technology: Advances in battery technology, such as solid-state batteries, offer higher energy density and faster charging times.

- Enhanced Motor Efficiency: New electric motors are more efficient, providing better performance and range.

Benefits:

- Zero Emissions: No tailpipe emissions, reducing environmental impact.

- Reduced Operating Costs: Lower cost of operation and maintenance compared to internal combustion engines.

Drawbacks:

- Range Limitations: Although improving, electric vehicles (EVs) still face range limitations compared to traditional vehicles.

- Charging Infrastructure: The need for extensive charging infrastructure can be a barrier.

1.2 Hybrid Engines

Overview: Hybrid engines combine traditional internal combustion engines (ICE) with electric motors to improve fuel efficiency and reduce emissions.

Recent Developments:

- Plug-In Hybrids (PHEVs): These vehicles can be charged from an external power source, allowing for longer electric-only range.

- Advanced Energy Management: Improved systems for managing energy flow between the electric motor and the ICE for optimal efficiency.

Benefits:

- Increased Fuel Efficiency: Better fuel economy compared to conventional ICE vehicles.

- Reduced Emissions: Lower emissions compared to traditional engines.

Drawbacks:

- Complexity: Hybrid systems are more complex, which can increase maintenance costs.

- Higher Initial Cost: Generally more expensive than standard ICE vehicles.

2. Turbocharging and Downsizing

2.1 Turbocharged Engines

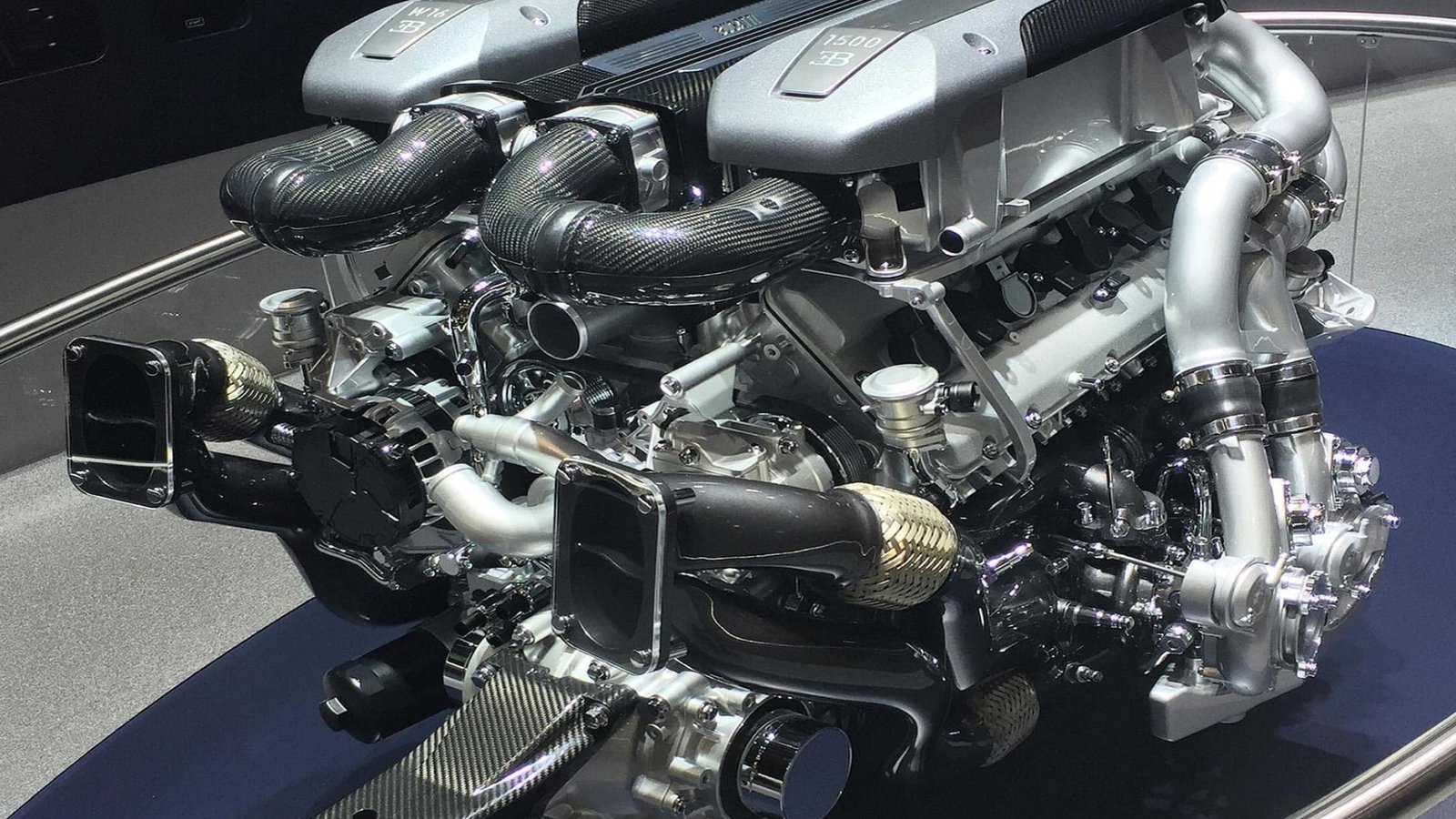

Overview: Turbocharging uses a turbine-driven forced induction system to increase engine power without significantly increasing engine size.

Recent Developments:

- Variable Geometry Turbochargers: These adjust the turbine’s geometry to optimize performance across different engine speeds.

- Electric Turbochargers: Utilize electric motors to spin the turbocharger faster, reducing lag and improving responsiveness.

Benefits:

- Increased Power: Provides more power from smaller engine sizes, improving performance.

- Better Fuel Efficiency: Smaller engines with turbocharging can achieve better fuel economy.

Drawbacks:

- Increased Complexity: Turbocharged engines have more components that can potentially fail.

- Heat Management: Turbochargers generate additional heat, requiring advanced cooling solutions.

2.2 Engine Downsizing

Overview: Engine downsizing involves reducing engine displacement while maintaining or improving performance through turbocharging or other technologies.

Recent Developments:

- Efficient Turbocharging: Coupling smaller engines with advanced turbocharging to achieve high power outputs.

- Enhanced Fuel Injection: Modern direct fuel injection systems help maintain performance with smaller engines.

Benefits:

- Improved Fuel Economy: Smaller engines generally consume less fuel.

- Lower Emissions: Reduced engine size leads to lower emissions.

Drawbacks:

- Power Limitations: Smaller engines may struggle with high-performance demands without turbocharging.

- Potential Reliability Issues: Smaller engines under higher stress might experience reliability concerns.

3. Variable Valve Timing and Lift

3.1 Variable Valve Timing (VVT)

Overview: VVT systems adjust the timing of the valve openings and closings to optimize engine performance across different RPM ranges.

Recent Developments:

- Advanced VVT Systems: Improved algorithms and actuators for better precision in timing adjustments.

- Continuous Variable Valve Timing: Offers smoother and more continuous adjustment of valve timing.

Benefits:

- Enhanced Performance: Optimizes power delivery and fuel efficiency.

- Reduced Emissions: Better control over combustion processes results in lower emissions.

Drawbacks:

- Complexity: Adds complexity to the engine design, potentially increasing maintenance needs.

- Cost: Higher initial cost due to advanced technology.

3.2 Variable Valve Lift

Overview: Variable valve lift systems adjust the amount of valve lift to improve engine performance and efficiency.

Recent Developments:

- Electrically Controlled Systems: Allow for precise control of valve lift for various driving conditions.

- Integration with VVT: Combining variable valve lift with VVT for optimal performance.

Benefits:

- Improved Efficiency: Adjusts valve lift for better fuel efficiency and power.

- Enhanced Performance: Provides better throttle response and power output.

Drawbacks:

- Maintenance: Additional components may increase maintenance requirements.

- Cost: More expensive due to advanced engineering and components.

4. Advanced Engine Materials

4.1 Lightweight Materials

Overview: Using advanced materials such as carbon fiber and aluminum alloys to reduce engine weight and improve performance.

Recent Developments:

- Carbon Fiber Components: Used in engine parts to reduce weight without compromising strength.

- Advanced Aluminum Alloys: Provide strength and durability while being lighter than traditional materials.

Benefits:

- Improved Performance: Reduces engine weight, enhancing acceleration and handling.

- Better Fuel Efficiency: Lighter engines contribute to overall vehicle efficiency.

Drawbacks:

- Cost: Advanced materials can be more expensive.

- Durability: Some lightweight materials may be less durable in harsh conditions.

4.2 High-Temperature Alloys

Overview: Engine components made from high-temperature alloys can withstand extreme temperatures and pressures.

Recent Developments:

- Improved Alloy Composition: Enhances strength and heat resistance.

- Durability: Increased lifespan of engine components under high stress.

Benefits:

- Enhanced Performance: Allows engines to operate at higher temperatures and pressures.

- Longevity: Increases the durability of engine components.

Drawbacks:

- Cost: High-temperature alloys can be more expensive.

- Complex Manufacturing: Requires advanced manufacturing techniques.

5. Hydrogen Fuel Cells

5.1 Hydrogen Engines

Overview: Hydrogen fuel cells generate electricity through a chemical reaction between hydrogen and oxygen, powering electric motors.

Recent Developments:

- Improved Fuel Cell Efficiency: Advances in fuel cell technology provide better energy conversion rates.

- Hydrogen Storage: Development of more efficient and safer hydrogen storage solutions.

Benefits:

- Zero Emissions: Only water vapor is emitted, making it environmentally friendly.

- Quick Refueling: Faster refueling times compared to electric vehicle charging.

Drawbacks:

- Infrastructure: Limited hydrogen refueling infrastructure.

- Cost: High cost of fuel cell technology and hydrogen production.

Conclusion

The latest innovations in engine technology are driving significant changes in performance, efficiency, and environmental impact. From electric and hybrid engines to advanced turbocharging and new materials, these advancements are shaping the future of automotive engineering. As technology continues to evolve, drivers can expect even more exciting developments that enhance their driving experience while contributing to a more sustainable future.